la minería de gas pequeña Meulage de pierre de piedra pulverizador

-

mungo faisant la machine

-

fonction de la lame de raymond broyeur

-

cot Guyane De Balle broyeur

-

brique d argile mâchoire concasseur afrique du sud nd main

-

moins broyeur de pierres prix philippines

-

prix des lignes de production de broyeur de pierres

Crushing Plant Design and Layout Considerations - 911

2024.9.24 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a

Bavarder sur Internet

Crushing Plant Flowsheet Design-Layout

2016.3.11 The majority of crushing plants recently constructed have accomplished this desired efficiency by optimizing plant design, crusher design and automation. By improved efficiency a decrease in energy consumption

Bavarder sur Internet

Improved dust capture methods for crushing plant

2007.2.1 The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust. Remedies to this

Bavarder sur Internet

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES - SGS

The lowest cost gold is normally produced by open pit mining with minimal crushing, followed by dump or heap leaching with cyanide. Gold recovery is usually around 80%, but can be as low

Bavarder sur Internet

Guidelines for mineral process plant development

2021.6.24 Guidelines for mineral process plant development studies P. R. Whincup* This paper presents guidelines for studies required for the development of mineral processing

Bavarder sur Internet

SIMULATION-DRIVEN DEVELOPMENT FOR COARSE

New needs are arising from the industry for existing operational crushing plants such as investigation for improvements, upscaling, and downscaling of the capacity. The paper

Bavarder sur Internet

DRILL-TO-MILL PLANT OPTIMIZATION AT ALTYNALMAS

2021.3.5 EMC’S drill-to-mill methodology has delivered significant benefits to the mine: increased fines from blasts (approximately 11% more -10 mm fines; reduced ROM F80 from

Bavarder sur Internet

Designing gold extraction processes: Performance study of a

2017.8.1 In this study, nine attributes: Ore type, Gold ore grade, Gold distribution, Gold grain size, Sulfide present, Arsenic sulfide, Copper sulfide, Iron sulfide and Clay present were

Bavarder sur Internet

Murchison Gold Portfolio - Monument Mining

The Murchison Gold Project (“Murchison”) includes the Burnakura, Gabanintha and Tuckanarra (20% free carry interest) properties, which are in the Murchison goldfield of Western Australia, 40km southeast of Meekatharra and 765km

Bavarder sur Internet

Crushing Plant: Surge Bins VS Stockpiles - 911Metallurgist

2016.2.29 Any multi-stage crushing plant will have a “bottle-neck” stage, and it is this stage which establishes the production rate of the entire plant; therefore, it should be kept busy, and the only way this can be done, if the feed to the plant is a fluctuating one, is to provide sufficient surge storage ahead of it to absorb such fluctuations ...

Bavarder sur Internet

Crushing Screening Plant Design Factors

2016.4.14 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced feed type of

Bavarder sur Internet

Gold Extraction Recovery Processes

2016.2.29 Crushing and Comminution. The selection of an appropriate crushing and comminution circuit for a specific ore type is one of the most important key aspects in a new gold project. The importance is related to the

Bavarder sur Internet

4-types-of-crushing-plant - Mining-pedia

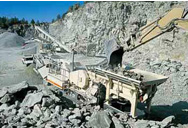

2021.5.25 Mobile crushing plant. Semi-mobile crushing plant. Semi-stationary crushing plant. Stationary crushing plant. Let’s drive in! Mobile Crushing Plant. The mobile crushing plant integrates feeding, crushing and conveying into one, using crawlers or tires to form a mobile mechanism, which can be adjusted in the mine according to the operational ...

Bavarder sur Internet

Crushing and Conveying OceanaGold - Waihi Operation - Waihi Gold

6 天之前 There are a number of conveyors required to ensure that following crushing, rock is transported to its correct destination. The largest conveyor on site (the overland conveyor) transports the ore from the open pit to the processing plant, and the waste rock to the waste rock embankments. Transfer stations move rock from one conveyor to the next.

Bavarder sur Internet

Parker Impressed By Hand-Built 25-Tonne Wash Plant! Gold

2024.8.13 A 25-tonne wash plant built by hand? Now that’s some serious DIY! ️⚒️ #GoldRushParkersTrail

Bavarder sur Internet

Types of Rock Crushers Quarry Crushing Equipment Kemper

3 天之前 Portable vs. Stationary Crushing Plants. Depending on the length of your project and how mobile your crushing equipment needs to be, you can choose either stationary or portable/modular crushing plants. Stationary plants have long been preferred because they feature a higher capacity and efficiency and lower production costs with easier ...

Bavarder sur Internet

Design of an open-pit gold mine by optimal pitwall profiles

2021.11.26 Flow chart illustrating how OptimalSlope interacts with Datamine to perform a pit optimization. From top to bottom: (1) OptimalSlope produces the optimal slope profile for the ultimate pit limit ...

Bavarder sur Internet

(PDF) Optimization Capabilities for Crushing Plants

2022.4.26 The optimization capabilities for crushing plants comprise a system solution with the two-fold application of 1) Utilizing the simulation platform for identification and exploration of operational ...

Bavarder sur Internet

Advantages And Disadvantages Of Four Different Crushing Plant

2024.7.23 The production of open-pit mines cannot work without crushing equipment. Adopting appropriate stone crushing plant can effectively reduce the effectiveness of ore and rock transportation and improve production efficiency. Stone crushing plant in open-pit mines include mobile, semi mobile, semi fixed, and fixed types according to the degree of fixation between

Bavarder sur Internet

Heap Leaching Agglomeration - 911Metallurgist

2017.6.13 The gold ore occurs in an oxidized disseminated deposit and averages 0.06 tr oz of gold per ton with trace amounts of silver. The host rock is porous and the gold is liberated by crushing. The ore is mined from an open pit and is friable. Seventy-five percent of the deposit can be mined with dozers and front-end loaders.

Bavarder sur Internet

Primary Crusher Optimisation for Improved Comminution

The first step in the mining and processing of nearly any mineral ore is comminution. Since the oil embargo of 1979, the mining companies have been striving to reduce energy consumption and costs. The first serious step was the introduction of in-pit crushing in the early 1980s. With in-pit crushing accepted as a standard design mode, the energy saving emphasis turned to

Bavarder sur Internet

In Pit Crushing and Conveying - RCR Mining Technologies

RCR Fixed In-Pit Solutions, often referred to as a Primary Crushing Plant (PCP), feature a combination of feeding, screening and/or crushing to handle up-front processing of various ores and applications including overburden removal, mineral sands, iron ore, coal, bauxite ore, gold ore and rock quarrying. Our Fixed In-Pit Solutions can be ...

Bavarder sur Internet

Simplifying the crushing process - Pit Quarry

2019.5.10 The answer might be three if you’re referring to stations in a complete crushing plant – primary, secondary and tertiary crushers. Of course, there are also different styles of crushers: compression-style jaw and cone crushers, for example, which fit into the various stations within a crushing circuit.

Bavarder sur Internet

In Pit Crushing and Conveying Systems - 911Metallurgist

2018.7.4 A general review of mine conveyor systems is followed by detailed analysis of the mobile and semi-mobile in-pit crushing plant essential to successful use of mine conveyors. Belt Conveyors Widespread in Soft-Rock Mining. In the soft-rock sector, positive experience with belt conveyors was gained in lignite mine-fields in the nineteen-fifties.

Bavarder sur Internet

Gold Processing Steps 101: Essential Guide - JXSC

2024.3.20 The World Gold Chamber says that in 2020, the nations that delivered the foremost gold were China, Russia, Australia, the United States, and Canada. These nations have a part of gold stores and have been mining gold for a long time, which makes a difference their economies develop and includes the sum of gold accessible around the world.

Bavarder sur Internet

First Gold from New Pit and Refurbished Plant

2024.8.23 First Gold from New Pit and Refurbished Plant Successful ramp up of Mineral Hill crushing, grinding, leaching and gold doré production Highlights: • Processing ramp up: Production through the crushing, grinding and CIL circuits continues to ramp up, with approximately 7000 tonnes of ore fed to date

Bavarder sur Internet

fire pit from a gold crushing plant - tablesandthyme.co

fire pit from a gold crushing plant - mhonsahotel. used crusher cone fire pit Mining Quarry Plant. sale crusher cones for fire pit alberta. we sell used crusher cones that make an ideal fire pit. they are made out of steel and are miniature portable sand crusher cone fire pit Mining Machinery is a professional material processing designer and supplier in the world, we have excellent ...

Bavarder sur Internet

(PDF) Field monitoring and performance evaluation of crushing plant ...

Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development. Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple ... This leads the mine plant to be set in a way which let the gold extraction process to be ...

Bavarder sur Internet

Crushing and grinding at Bond Gold’s Colosseum mine : An

Bond International Gold's Colosseum gold mine was discovered in 1865. No recorded production occurred, however, until the 1930s, with production of about 19 kg (615 oz) of gold. The mine was closed in 1942 as a nonessential industry during World War II. The property was acquired by Dallhold Resources in mid-1986. Construction of a 1.1-million Mt (1.2-million st), carbon-in

Bavarder sur Internet

Articles liés

- béton de recyclage des déchets broyeur à rouleau

- Come funciona os equipamentos para o Minera

- screaners de sable vibrant

- des étapes de traitement de minerai de fer

- broyeur de pierres pour l iran

- kaolin machoire fournisseurs de concasseurs a indonessia

- broyeur de pierres tout simplement

- concasseur mobilecrushingplantforsale concasseur mobile

- os de viande machine a chaudière concasseur

- principes de broyeurs à marteaux concasseurs à mâchoires 2c

- la poudre de silice broyage

- pierre de concassage pour la location

- Afrique concasseur de pierre Indonésie Delhi

- usine de transformation de cacao en poudre en haiti

- Or De Flottation Et Minerais De Manganèse

- nantou exploitation minière burkina faso sa

- le prix des convoyeurs

- pierre de concassage au Pakistan

- pierre et de sable lavage au Pendjab

- Concasseur de broyage Fabricants Intitulé

- minerai de fer concassage en tanzanie

- allemagnepresentation de concassage de pierre

- centrales électriques au charbon de traitement

- visão de cima do britador do cone

- incidence calcaire broyeur

- les mines de charbon palaran

- molino de rodillos de ferrell ross

- fraiseuse paillasse pour le bois

- broyeur de pierres disponible en Inde avec le prix

- le minerai de fer broyeur Indonésie boulets broyage