broyeur pour dalles de faux plafond

-

broyeur de Dolomite Maroc

-

machine de traitement des pierres précieuses

-

Specification Broyeur A Boulets De Broyage De Calcaire

-

séparateur magnétique à chaîne

-

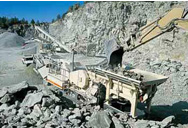

Forme Complete De Machinerie De Concassage Vsi

-

broyeurs pour l'industrie du ciment photos

Claybath versus hydrocyclones for cracked mixture separation – PALM OIL ...

3 天之前 This paper deals with the comparison in separation performance by hydroclay baths and hydrocyclones in handling cracked mixture obtained from thin shell nuts’ of the Tenera [D

Bavarder sur Internet

The Adaptation of Clay -Bath and hydro cyclones in Palm

2014.7.10 scale and large-scale palm mills. In this paper, the authors aimed at narrowing the information gap by revealing how to adapt the clay-bath and hydro-cyclones in palm nut

Bavarder sur Internet

The Adaptation of Clay-Bath and hydro-cyclones in Palm Nut

The palm oil industry (POI) generates significant amounts of waste, including calcium carbonate (CaCO3) from the clay bath system used for the separation of palm kernels from shells. This

Bavarder sur Internet

(PDF) Synthesis of Resource Conservation

2010.1.1 The focus is given to the clay bath system for solid separation based on density differences. In the present study, the clay bath is modeled as a semi-batch unit with dynamic changes.

Bavarder sur Internet

Schematic diagram of a clay bath system

Jan 2010. Cheng-Liang Chen. Jui-Yuan Lee. Denny K S Ng. Dominic Chwan Yee Foo. This work presents a mathematical model for resource conservation in a palm oil milling process via property...

Bavarder sur Internet

(PDF) Adaptation of claybath olisaemeka nwufo

Suggest possible ways these innovations could be adapted for use, especially, by small-scale palm mills. This study will help indigenous small scale industries adopt modern techniques in the cracked mixture to obtain palm kernel and

Bavarder sur Internet

Synthesis of Resource Conservation Network for the Clay Bath

2010.8.20 Synthesis of Resource Conservation Network for the Clay Bath System in Palm Oil Mills. Research Articles. doi/10.3303/CET1021152. Published 20 August 2010.

Bavarder sur Internet

Anaerobic Digestion of Palm Oil Mill Residues for Energy

2017.8.29 A hydrocyclone or a clay bath is used to further separate the mixture of palm kernel and nutshells. The clay bath principle works on the specific gravity of kernels of 1.07

Bavarder sur Internet

Application of oiler Fly Ash for Oil Palm Kernel

effective weight variation of palm oil mill boiler ash as a separator material in clay baths as a substitute for calcium carbonate and termite clay and its application in clay baths.

Bavarder sur Internet

The Adaptation of Clay-Bath and hydro-cyclones in Palm Nut

KEY WORD: adaptability, clay bath, hydro-cyclones, palm-nut, cracked mixture. Oil palm is now accepted as one of the most important oil-producing crops in the world. The bid to ensure efficient and quality production has resulted in the invention of machines that have greatly reduced human labour in the production process. ... Palm oil mills ...

Bavarder sur Internet

Anaerobic Digestion of Palm Oil Mill Residues for Energy Generation

2016.8.11 A hydrocyclone or a clay bath is used to further separate the mixture of palm kernel and nutshells. The clay bath principle works on the specific gravity of kernels of 1.07 and the shell of 1.17. ... Palm oil mill wastewater from the production process was pre-treated by oil recovery tank and primary ponds before feeding to the anaerobic ...

Bavarder sur Internet

Application of Boiler Fly Ash for Oil Palm Kernel

2022.12.21 Palm oil mill boiler ash is one of the substances that can be used as an adsorbent. The adsorbent can absorb certain components of a fluid phase, which before being applied needs to be activated ...

Bavarder sur Internet

clay bath palm oil mill

The Adaptation of Clay-Bath and hydro-cyclones in Palm Nut The clay-bath has been recommended for local mill operators for cracked hydro-cyclones in palm nut cracked-mixture separation to small–scale oil palm(PDF) Th...

Bavarder sur Internet

Waste Minimisation for Palm Oil Mills: A Case Study

2021.12.4 with 443 palm oil mills in operation (MPOB Statistics, 2015). The production of crude palm oil (CPO) was 19.96 million tonnes in 2015, contributing to more than 33.15% of the world production of palm oil. However, the production of palm oil also generated a large amount of palm oil mill effluent (POME) at the average production rate of 0.67 t-1 FFB

Bavarder sur Internet

Application of oiler Fly Ash for Oil Palm Kernel

Oil palm fruit processing is one of the factors that determine success in the palm oil industry. The main products of oil palm fruit processing are crude palm oil (PO), palm kernel, shells, fiber (Setyawan, 2014). Generaly, Palm Oil Mill (POM) has several processing stations, namely sortation station, sterilization station, threshing station,

Bavarder sur Internet

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum - Oil

4 天之前 The clay-bath uses a clay solution that is maintained at a pre-determined density.When the cracked mixture is admitted into the clay-bath, the denser shells will sink to the bottom while the less dense kernels will float.

Bavarder sur Internet

Characterization of waste clay from palm oil mill effluent and

The final POME is the combination of different sources within palm oil mill such as condensate from the sterilization process, sludge from the clarification process, and clay bath from the hydrocyclone process. Clay bath is a technique to separate the

Bavarder sur Internet

En Bulletin 82 new - Malaysian Palm Oil Board

2021.12.4 When people talk about palm oil mills, the product that gets most highlighted is ... Hydro-cyclone stage 1 in combination with clay bath - a good system that can reduce calcium carbonate consumption. based on the high percentage of kernel

Bavarder sur Internet

Palm Oil - AOCS

The clay bath principle works on the specific gravity of kernel of 1.07 and the shell of 1.17. The kernels will float while the shells sink in a clay bath mixture of SG 1.12. ... A palm oil mill produces an average of 0.65 tons of raw palm oil mill effluent (POME) from every ton of FFB processed. POME is the main cause of environmental ...

Bavarder sur Internet

Potential of Energy Recovery from an Integrated Palm

2020.1.6 oxygen demand (COD) of the POME were obtained from the laboratory at the palm oil mill whereas the heat engines operating data were collected from the biogas power plant of this case study. 3. Findings 3.1 Palm oil mill material and energy balance Figure 1 shows the process block diagram of integrated palm oil mill with biogas power plant based on

Bavarder sur Internet

Anaerobic Digestion of Palm Oil Mill Residues for Energy

2017.8.29 A hydrocyclone or a clay bath is used to further separate the mixture of palm kernel and nutshells. The clay bath principle works on the specific gravity of kernels of 1.07 and the shell of 1.17. Separation is achieved when the kernels float while the shells sink in a clay bath mixture of specific gravity of 1.12.

Bavarder sur Internet

Synthesis of property-based resource conservation network in palm oil ...

2011.4.2 This article presents a mathematical model for resource conservation in a palm oil milling process via property integration. The focus is given to the clay bath system for kernel/shell separation based on flotation principle. In the present study, the clay bath separator is considered as a semi-batch unit under time-dependent process disturbance. This is different from

Bavarder sur Internet

[PDF] Synthesis of Resource Conservation Network for the Clay Bath ...

2010.8.20 Corpus ID: 55612343; Synthesis of Resource Conservation Network for the Clay Bath System in Palm Oil Mills. @article{Chen2010SynthesisOR, title={Synthesis of Resource Conservation Network for the Clay Bath System in Palm Oil Mills.}, author={Cheng-Liang Chen and Jui-Yuan Lee and Denny Kok Sum Ng and Dominic Chwan Yee Foo}, journal={Chemical

Bavarder sur Internet

The Adaptation of Clay -Bath and hydro cyclones in Palm

The clay-bath has been recommended for local mill operators for cracked mixture separation due to its ease of use and scalability. KEY WORD: adaptability, clay bath, hydro-cyclones, palm-nut ...

Bavarder sur Internet

A diagram showing the cyclone action of a hydrocyclone.

These data indicate that the density of palm kernels and shells used in this study ranged from 1.05 to 1.09 g/cm3 and 1.19 to 1.32 g/cm3, respectively.

Bavarder sur Internet

Reutilization of Real Waste Calcium Carbonate (CaCO3) from the Palm Oil ...

2024.11.1 The palm oil industry (POI) generates significant amounts of waste, including calcium carbonate (CaCO3) from the clay bath system used for the separation of palm kernels from shells. This CaCO3 waste is often discarded, leading to environmental issues. However, the CaCO3 can potentially be reused in the clay bath separation process to improve efficiency and

Bavarder sur Internet

Saline Bath System for Separation of Palm Kernels from Shells

Separation of palm kernels from cracked shells of the oil palm fruit is a difficult step in the production of palm kernel oil. An appraisal of the traditional clay-water bath separation method showed that the method was based on the difference in specific gravity of the palm kernels and the shells. The method was efficient but it was associated with many disadvantages which

Bavarder sur Internet

Synthesis of Resource Conservation Network for the Clay

the clay bath system in palm oil mills, Chemical Engineering Transactions, 21, 907-912 DOI: 10.3303/CET1021152 ... Figure 1(a) shows a schematic diagram of a clay bath system to separate palm kernel

Bavarder sur Internet

Synthesis of Resource Conservation Network for the Clay

2018.5.28 the clay bath system in palm oil mills, Chemical Engineering Transactions, 21, 907-912 DOI: 10.3303/CET1021152 Synthesis of Resource Conservation Network for the Clay Bath System in Palm Oil Mills Cheng-Liang Chen1*, Jui-Yuan Lee1, Denny Kok Sum Ng2, Dominic Chwan Yee Foo2

Bavarder sur Internet

Articles liés

- plantes concasseur de entrepreneurs afrique du sud

- garantie du fabricant de concasseur de calcaire

- concasseur de quartz technologie

- larges ponceuses de ceinture à taiwan

- broyage et épaississement de lor

- l operation concasseur de verre

- concasseur pierre jatim harga bekas

- jaypee unite de broyage de ciment bina en France

- pennsylvanie concasseur à mâchoires à vendre

- feldspath et de Gravier de traitement

- machine de bloc au mexique

- qual o preco de um britador industrial

- minerai concentré par séparation magnétique

- z&233;nith de lecteur dvd portable

- usine de ciment Tataouine

- Comment Se Fait L Extraction Du Minerai De Fer

- pour la calcination du gypse en Inde le depistage de gypse

- particules rouleau de concassage

- broyeur de pierre tph taux

- Processus de concassage de la bauxite

- hitachi 420 informations concasseur mobile

- un aperçu de la concentration de l aluminium

- animal feed milling machines

- cône concasseur près manquer

- pieds concasseurs afrique du sud a vendre

- simons joints de concassage 7ft

- conception sable de silice nettoyage de l usine et le co t

- mina de ouro tecnologia de extracão de rejeito

- sev appel moulin bille en carbure

- broyeur de granit fournisseurs au nigeria