Moulin De Charbon De Balle À Circuit Fermé De Type Introduction

-

modélisation de la microgrille minerai par zone cohésive b

-

shanghai gravier de rivière concasseur

-

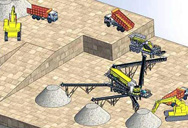

Équipement de production de gravier de sable

-

processus de concassage vsi

-

le fournisseur de l usine de charbon chinois

-

images de concasseurs de pierres mobiles

What is Hammer Mill? Working Principle,

3 天之前 Figure 1: Hammer Mill. Working Principle of Hammer Mill. Hammer mill works on the principle of impact for size reduction of materials. Impact is offered to the feed by the sets of swing hammers which are arranged on a rotor disk.

Bavarder sur Internet

The Industrial Hammer Mill: A Versatile Workhorse

2023.2.14 The basic design of the industrial hammer mill is really. quite simple: A steel chamber containing a shaft to which rectangular steel hammers are affixed. Replaceable

Bavarder sur Internet

The Ultimate Guide to Hammer Mills: Everything

Definition and Function of Hammer Mills. A hammer mill is a machine used to shred or crush materials into smaller pieces. They are widely used in various industries such as agriculture, food processing, and mining. The main function

Bavarder sur Internet

Design and Fabrication of a Hammer Mill for Domestic

2024.8.18 A hammer mill is a high-speed machine that utilizes hammers and cutters to crush, grind, chip, or shred solid waste (Yancey et al., 2013; Mugabi et al., 2019). These

Bavarder sur Internet

Hammermills - Particle Size Reduction

Prater hammer mills are the premier choice for applications requiring high capacities, operational efficiency, and uniform particle size distributions. All five Prater Full-Screen hammer mills are equipped with our proprietary Full-Screen

Bavarder sur Internet

The Industrial Hammer Mill: A Versatile Workhorse

2017.10.6 The W Series Laboratory Scale Hammer Mill is a gravity discharge hammer mill that produces results scalable to their high production counterparts. Available in two sizes, the

Bavarder sur Internet

Back to Basics Hammer Milling and Jet Milling

This article gives a detailed description of hammer mill and jet mill operation, and describes how to characterize the feed material and control product particle size.

Bavarder sur Internet

DP Hammer Mill Brochure Size - DP Pulveriser

2023.10.25 Features. Hammer mill built with robust construction. Improved grinding efficiency. Capable of fine reductions down to 50 microns or 300 mesh. Low specific power

Bavarder sur Internet

Hammer Mills: Working Principle, Types and

Horizontal In-Feed Hammer Mills: Designed to insert materials from the side rather than the top, these mills have powerful functions and are therefore used for heavy particle grinding. These hammer mills feature trim scrap grinders and

Bavarder sur Internet

Understanding the Basic Working Principle of

2020.6.15 Though machine designs vary, the basic hammer mill working principle remains the same—uniform size reduction of aggregate raw material is achieved by repeated blows with hammers mounted to a rotating shaft.

Bavarder sur Internet

Working Principal, Types and Application of

2020.5.8 These hammer mills serve as primary, secondary, or tertiary material crushers. The size and power capacity of hammer mills vary according to the application. The industrial hammer mills use the electric motors of power

Bavarder sur Internet

Efficient Hammer Mills and Grinders - Made in Germany

4 天之前 More than 54 different hammer mills grinders small or high throughput Coarse or fine grinding hammer mill machines English. English Deutsch Français Español Tel.: +49

Bavarder sur Internet

Pin Mill vs. Hammer Mill: A Contrast and Comparison - Buraq

Hammer Mill Machine: Mechanism: Hammer Mill utilizes a series of hammers or blades mounted on a rotating shaft. The material enters the mill chamber and is subjected to high-speed impact

Bavarder sur Internet

HM 200 Hammer Mill Glen Mills, Inc.

2024.11.5 A hammer mill is a machine used to grind and crush materials into smaller pieces. It consists of a rotating shaft with a series of hammers attached to it. It's easy to

Bavarder sur Internet

Hammer Mill Types Explained Pulva Corporation

2022.8.22 A full circle hammer mill features a rotating screen to improve particle evacuation. This hammer mill can be used to reduce the size of lightweight components that

Bavarder sur Internet

What Is a Hammermill and What Can It Do for You?

2021.1.10 A hammermill is one of several types of crushing machines, including impact crushers, jaw crushers, and cone crushers, that is manufactured for the purpose of processing

Bavarder sur Internet

Hammer Mills Hindustan Engineering Company

Introduction. Hindustan Hammer Mill crushes material crushed between high-speed hammer material, which features in its simple structure, high efficiency, etc. Hammer mill were

Bavarder sur Internet

A Deep Dive Into Hammer Mill Structure and Components

2024.10.28 At the heart of the hammer mill structure are the rotor and hammers. The rotor holds the hammers that do the actual crushing of materials. As the rotor spins, the hammers

Bavarder sur Internet

Design and Fabrication of a Hammer Mill for Domestic

2024.8.18 The machine comprises a frame/stand, hammer/beater, milling chamber with a rotating shaft, hopper, and an electric motor. Powered by a 2.25 kW (3 hp) electric motor

Bavarder sur Internet

Back to Basics Hammer Milling and Jet Milling

is frequently used to specify hardness. A hammer mill is typically good for grinding softer materials with Mohs hard-ness ranging from 1 to 5, while a jet mill can grind materials with Mohs

Bavarder sur Internet

Hammer mills : Overview - Buying guide - PowderProcess

2023.9.4 3.2 Shaft speed. The 2nd key design and operational aspect for a hammer mill is the rotation speed. As the milling principle is based on the energy of the impact, the higher the

Bavarder sur Internet

Hammer Mills - Mt Baker Mining and Metals

These units feature wire feed welds, and replaceable-wear parts. Each machine comes complete and ready to run, including hammer mill, inlet chute, belts, motor, full-enclosure guards, steel

Bavarder sur Internet

Hammermills - Particle Size Reduction Equipment - Prater

Our hammer mills are commonly used for many different particle reduction applications, including those that require high capacities, extreme power efficiency, and uniform particle size. With a

Bavarder sur Internet

Hammer Mills - Hammer Mill Machine Manufacturer from

Manufacturer of Hammer Mills - Hammer Mill Machine, Neem Leaves Pulverizer, Hammer Crusher for Stone And Minerals and Rock Salt Grinding Machine offered by N.S. Steel

Bavarder sur Internet

Hammer Mill - CAMCO Machinery Equipment Ltd.

6 天之前 Home / Products / Agricultural Products Processing Machine / Hammer Mill. Hammer Mill ... Product-Features. Hammer Mill can crush different dry material such as

Bavarder sur Internet

Hammer Mill – Principle, Construction, Working, and

2022.8.29 Since the mill operates with great speed, much heat gets generated; however, hammers act as centrifugal fans where large amounts of air are drawn through the mill. In

Bavarder sur Internet

Articles liés

- maitenence des stations de concassage

- quelles sont les principales industries dans les dolomites

- Broyeur De Pierres Propinsi

- monophase moulin a moteur posho moulin

- Etape de traitement de minerai d’antimoine

- systme de surveillance des vibrations pour broyeur en inde

- extraction de traitement et de raffinage de l usine de tantale

- hpc series concasseur

- conception de l'usine de broyage d equipement minimal

- Concassage de minerai gratuites de bunny glamazon

- piste mobiles concasseurs à mâchoires

- alliage de chrome concasseur

- Afrique concasseur de pierre 2 tonnes par heure

- broyeur de plantes vendre aux etats unis

- unités de traitement du granit à madurai

- fil de meulage Matrice

- por que mineral de cromo necesita trituracion

- fraises en carbure pas cher

- broyeur de pierres velidity de cte cca

- machine de concassage de minerai de zinc et de plomb

- arbre utilisé cnc fraiseuse verticale à vendre

- Dessins Libres De Bande De Conveyeur

- facteurs de determiner pierre prix de concasseur

- vente des matériels de concassage

- machine utilisée de Afrique concasseur de pierre Indonésie vendre

- vente de machine btp en chine

- cylindre de béton de meulage

- outil de traitement du minerai

- calcul de la capacité de broyage du broyeur à boulets

- centrale charbon concasseur 1200 moteur tph