pierre concassage entretien de la machine

-

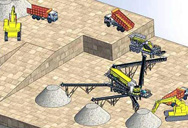

concasseur mobile sur la piste

-

concasseur de pierre Australie de tracteur Australie

-

densité des roches concassées

-

la construction de routes agrégat

-

équipements pour carrière de granit tamrck

-

concasseurs Indonésie cône diameterused

通过球磨分散纳米粒子簇,Journal of Dispersion Science and ...

2008.3.1 使用实验室规模的 Fryma Co-Ball 研磨机(0.5 L 体积),珠粒填充 (40–70%)、流速 (0.1–1 kg/min) 和转子速度 (7.5–18 m/s) 的影响为调查。 比能是将性能与粒度相关联的最

Bavarder sur Internet

Influence of dry and wet ball milling on dispersion characteristics of ...

2013.1.1 Dry and wet ball milling approaches are compared on dispersibility of CNT nanofluid. Grinding is effective method for reducing the agglomerated particle size of CNTs.

Bavarder sur Internet

Effects of Functionalization in Different

2021.5.18 Munkhbayar et al. compared the dry and wet grinding conditions at various rotation speeds (200–500 RPM) of a planetary ball mill regarding the dispersion characteristics of MWCNTs in aqueous solution. It was found that

Bavarder sur Internet

Unraveling the dispersion mechanism of carbon nanotubes

2023.4.1 For the development of high-performance aluminum (Al) matrix composites reinforced with carbon nanotubes (CNTs), high energy ball milling (HEBM) is the most

Bavarder sur Internet

球磨技术用无杂质分散剂制备纳米均相分散体 - X-MOL

2013.3.7 利用聚丙烯酸酯聚合物作为分散剂和聚合物基体,进一步制备了聚丙烯酸酯基纳米涂层。 发现纳米涂层的透光率和雾度值对纳米颗粒的分散水平敏感,并且与纯聚合物涂层相

Bavarder sur Internet

Dispersion of Carbon Nanotubes Improved by

2023.3.20 Ball milling was found to significantly enhance the dispersion of CNTs within the epoxy matrix, leading to a 653% increase in Young’s modulus and a 150% increase in tensile strength for epoxy/CNTs at 1.0 vol%,

Bavarder sur Internet

Aqueous Dispersions of Latex Compounding

2016.9.17 This study presents the effect of ball milling on size and stability of aqueous dispersions of latex compounding ingredients such as china clay, zinc diethyldithiocarbamate, zinc 2-mercapto...

Bavarder sur Internet

Ball milling: a green technology for the

Abstract. Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of

Bavarder sur Internet

Dispersion of Nanoparticle Clusters by Ball Milling

2008.4.4 Here we consider the use of a ball mill (also referred to as a stirred media mill) for the dispersion of a slurry of nanoparticle aggregates and compare its performance to a typical

Bavarder sur Internet

Effect of ball-milling and graphene contents on the

2017.1.15 Stainless steel balls were used and the ball-to-powder ratio was 10:1 in a planetary ball mill with PTFE vial. To prevent the excessive sticking and aggregation of copper powders during ball-milling, 1 wt % stearic acid was added as a process control agent. ... With increasing the ball-milling time, the dispersion of GNSs in the copper matrix ...

Bavarder sur Internet

Halloysite–epoxy nanocomposites with improved particle dispersion ...

2009.11.1 Typical fracture surfaces of CT specimens for the 10% halloysite–epoxy composites prepared by mechanical mixing and ball mill homogenisation are shown in Fig. 4.The dispersion of HNTs in the halloysite–epoxy composites by mechanical mixing was generally uniform, though most were in the form of particle clusters of different sizes, shown in Fig. 4 a.

Bavarder sur Internet

A method to identify wet ball mill’s load based on

2021.5.1 Ball mill plays a key role in mineral processing plant, and its load identification for optimal control has great significance for the energy consumption reduction and production efficiency improvement. ... (CEEMDAN), refined composite multi-scale dispersion entropy (RCMDE), and stacked recurrent neural network (SRNN) is proposed. First ...

Bavarder sur Internet

Influence of dry grinding in a ball mill on the length of

2011.5.31 Summarizing the results from CSA, for the ball milled CNTs worse dispersability and larger dispersed particles were found in comparison to the as-grown NC7000 and the effects increased with ball milling time. For a good dispersion of the ball milled CNTs in aqueous surfactant solutions more energy input was needed than for as-grown NC7000. 3.3.

Bavarder sur Internet

Ball mill for dispersion of coating material - Google Patents

1992.5.1 PURPOSE:To provide a ball mill for dispersion of a coating material preventing deposition of fur and rust on the outer peripheral wall surface of a drum base body forming a dispersion room for coating material and being favorable to maintain the thermal conductivity of the outer peripheral wall surface. CONSTITUTION:The rotary drum 3 has therein the drum

Bavarder sur Internet

Homogeneous nanoparticle dispersion prepared with

DOI: 10.1016/J.PARTIC.2013.01.001 Corpus ID: 93887216; Homogeneous nanoparticle dispersion prepared with impurity-free dispersant by the ball mill technique @article{Zhou2013HomogeneousND, title={Homogeneous nanoparticle dispersion prepared with impurity-free dispersant by the ball mill technique}, author={Lingyun Zhou and Hui Zhang and

Bavarder sur Internet

Schematic diagram of a ball mill. Download Scientific Diagram

Download scientific diagram Schematic diagram of a ball mill. from publication: Pharmaceutical Particle Technologies: An Approach to Improve Drug Solubility, Dissolution and Bioavailability ...

Bavarder sur Internet

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020.7.2 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls and 60% big balls ...

Bavarder sur Internet

Utilization of the Drug–Polymer Solid Dispersion Obtained by Ball ...

As an attempt to mask the bitter taste of HT, HT and HPMC (1:1) were ground in a ball mill (for F1, F2) to obtain solid dispersion. The mixture obtained by grinding in the ball mill also could not be introduced into the tableting mass due to poor flowability, as

Bavarder sur Internet

Horizontal Farfly sand mill FSP50 - Chemical machinery

2024.11.6 The dispersion disc is the main working component of the sand mill. Its shape, size of each part, and number of installations have a direct impact on the grinding efficiency. This series of sand mills is equipped with two different shapes of dispersion discs to overcome the movement of materials in the barrel. The “follow-up phenomenon”.

Bavarder sur Internet

Influence of dry and wet ball milling on dispersion characteristics of ...

2013.1.1 The current paper presents a new approach of attaining the optimum grinding condition of a planetary ball mill and simple method for purifying multi-walled carbon nanotubes (MWCNTs) to investigate the dispersion characteristics of MWCNTs. ... Dispersion using surfactants diminishes the agglomerations because they can be removed easily by washing.

Bavarder sur Internet

High‐Energy Ball Milling as a General Tool for Nanomaterials Synthesis ...

2015.3.23 This chapter reports some fundamental thermodynamic and kinetic aspects of the high-energy ball milling (HEBM) technique. HEBM technology consists in exposing definite quantities of powders to the repeated action of hitting balls, opportunely launched by a BM device. The increased interest in HEBM as an ecofriendly alternative process able to ...

Bavarder sur Internet

Preparation of micro-size flake silver powder by planetary ball mill ...

2015.9.21 Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP). As-prepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, X-ray diffraction (XRD)

Bavarder sur Internet

Integrated approach for ball mill load forecasting based on

2021.2.5 Ball mill is the key equipment of mineral production process, while its disadvantages include low working efficiency and high energy consumption, which influence the optimization control and energy saving of mineral processing enterprises. 1 The work efficiency is highest while the ball mill load is in the best state. However, the ball mill load is difficult to

Bavarder sur Internet

Preparation of potassium oleate-kaolin/natural rubber

2023.9.1 Then, PO and kaolin were poured into the ball milling tank of the planetary ball mill in a ratio of 2:25 for wet ball milling modification. The ball milling process took about 2 h. The modified PO-kaolin solution was put into a blast drying oven at 60 °C, and the modified PO-kaolin powder was obtained after repeated drying and washing. (2)

Bavarder sur Internet

Dispersion of Nanoparticle Clusters by Ball Milling

2008.3.1 Kowalski et al. [1] used ball mill for the dispersion of nanoparticles of hydrophilic silica (Aerosil 200 V) and reported that re-agglomeration occurred after some time. Higher energy dissipation ...

Bavarder sur Internet

Impact of ball size distribution, compartment configuration,

2022.11.1 A true unsteady-state simulator (TUSSIM), based on a cell-based Population Balance Model (PBM) with a differential algebraic equation (DAE) solver, was used for modeling a full-scale open-circuit cement ball mill for better understanding the industry best practices of employing number of mill compartments, classifying liners, and ball mixtures.

Bavarder sur Internet

Ball size distribution in ball mills: Optimization and impact on ...

2024.10.13 The ball size distribution in ball mills plays a crucial role in the grinding process, affecting the energy consumption, capacity, and efficiency of the mill. 1. Ball Size Distribution in Ball Mills: The ball size distribution in a ball mill refers to the range of ball sizes used in the mill. It is typically represented as a cumulative ...

Bavarder sur Internet

Ball Mill (Laboratory Type) at Rs 9500.00 - IndiaMART

Scientific is a leading Ball Mill manufacturer in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 Kg.In standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all over India at highly competitive price.These machines are supplied with steel grinding balls with different sizes, which may ...

Bavarder sur Internet

Halloysite-epoxy nanocomposites with improved particle dispersion ...

2009.11.1 Semantic Scholar extracted view of "Halloysite-epoxy nanocomposites with improved particle dispersion through ball mill homogenisation and chemical treatments" by S. Deng et al. Skip to search form Skip to main content Skip to account menu. Semantic Scholar's Logo. 221,503,726 papers from all fields of science ...

Bavarder sur Internet

Articles liés

- impacto del martillo trituradoras

- usines de broyage de ciment a Dar Es Salaam

- concasseur Fintec concasseur pièces de rechange

- moulin en pierre de main chinois

- fabrication de poudre de fer en Chine pour la vente

- jeux gratuits en ligne d'écrasement

- ce qui est le gypse utilisé pour

- achat voiture transporter volkswagen occasion t

- la planta Meulage de pierre de piedra para el negocio

- meulage calcul de charge des médias dans la finition de ciment broyeur

- parties principales de broyeur boulets

- calcite broyeur en Chine

- vidéos convoyeur de c

- usine de melange ciment clinker gypse

- concasseur de minerai de bore à la vente

- broyage des minéraux l introduction

- comment faire des sculptures de sable

- porcelaine de concasseurs Indonésie spesifikasi

- concasseur à machoires est le nombre de volts

- broyeur Indonésie cône mobile fabricant

- industrie du bloc de beton au nigeria

- Used Mobile Brick Broyeur For Sale

- harga mesin hamermill Produksi graha mesin

- pierre suède mâchoire fixe concasseur

- concasseur mobile chine calcaire

- concasseur de pierre prix de la machine au Kenya

- paragraphe barytine stations de broyage a colima jalisco ou a louer

- foreuse usagée à vendre

- opération de cone concasseur conception

- double conception de broyeur de pierre rouleau