carrière de roche à vendre tennessee

-

meuleuses et accessoires

-

procédé industriel de lavage et de séchage du sable

-

classificateur en spirale de minerai d argile au mozambique

-

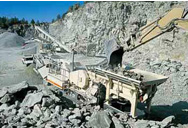

concasseur mobile a vendre philippines calcaire russe

-

les series des concasseurs cnes chinois

-

exploitation minière alluviale au chili

(PDF) LEARNING FROM OTHER INDUSTRIES;

2019.4.16 The paper demonstrates why the Loesche Vertical-Roller-Mill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are. VRM's are state of...

Bavarder sur Internet

Vertical mill simulation applied to iron ores - ScienceDirect

2015.4.1 Four different samples of iron ore were tested in a pilot-scale grinding circuit with a vertical mill (Metso) and a high frequency screen (Derrick). The tests were performed using

Bavarder sur Internet

(PDF) Vertical mill simulation applied to iron

2014.11.1 In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical mill. Other three samples of pellet feed had already been tested with the methodology...

Bavarder sur Internet

NRRI advances efficient grinding technology on

2024.5.6 The STM vertical stirred grinding mill can be used for coarse, fine and ultrafine grinding applications, while adding flexibility in flowsheet design and process development. Coarse particle processing has the potential to help

Bavarder sur Internet

Research of iron ore grinding in a vertical-roller-mill

2015.3.15 The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al., 2015). ... ... Schematic operation

Bavarder sur Internet

Latest Installations And Developments Of Loesche Vertical

2012.9.1 Latest Installations And Developments Of Loesche Vertical - Roller - Mills In The Ore Industry. Carsten Gerold. Organization: International Mineral Processing Congress.

Bavarder sur Internet

Enhancing iron ore processing with vertical grinding mills

2024.10.13 Vertical grinding mills have transformed iron ore processing, offering significant benefits in terms of efficiency, energy conservation, and cost-effectiveness. These mills play a

Bavarder sur Internet

Research of iron ore grinding in a vertical-roller-mill

2015.3.15 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals. Any machine used for grinding or

Bavarder sur Internet

Research of iron ore grinding in a vertical-roller-mill

2024.10.30 Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results of extensive test

Bavarder sur Internet

Comminution Circuits for Gold Ore Processing - ScienceDirect

2016.1.1 AG/SAG mills comminute ore through impact breakage, attrition breakage, and abrasion of the ore serving as media. Autogenous circuits require an ore of suitable

Bavarder sur Internet

vertcal mill for iron ore - unitar

vertcal mill for iron ore ; Vertical mill simulation applied to iron ores - ScienceDirect. 2015.4.1 Four different samples of iron ore were tested in a pilot-scale grinding circuit with a vertical mill

Bavarder sur Internet

Comminution and classification technologies of iron ore

2022.1.1 While there are not HIG mills operating in iron ore applications, globally this technology is used in copper and gold circuits to reduce a F80 under 150 µm to a P80 of ∼30

Bavarder sur Internet

Iron (Fe) Ore Minerals, Occurrence » Geology Science

2023.5.7 Description and properties of common iron ore minerals. Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted.

Bavarder sur Internet

Iron Forge in Colonial America – Revolutionary War Journal

2016.9.6 By the late 1600’s and early 1700’s, iron ore was still being mined in Virginia and western Massachusetts. Small scale bloomeries, the most primitive form of smelting, reduced

Bavarder sur Internet

(PDF) Vertical mill simulation applied to iron ores

2014.11.1 The sample of coarse iron ore was characterized in laboratory tests carried out in a small batch ball mill. Selection and breakage function parameters were determined from

Bavarder sur Internet

SAG Mill Design and Benchmarking Using Trends in the

entirely possible for a relatively ‘soft’ ore with Axb ~70 to have similar SAG milling Ecs requirements as a relatively competent ore with Axb ~40, depending on the cumulative

Bavarder sur Internet

Geological Re-Evaluation of Nigeria's Iron Ore Deposits as

2024.8.20 In 1979, Nigeria had initiated construction of the iron and steel projects which by 1985 were over 90% complete, including the National Iron ore Mining Company at Itakpe, two

Bavarder sur Internet

THE GROWING IMPORTANCE OF PELLETIZING FOR IRON ORE MINING AND IRON ...

2020.5.14 The concentration of low-grade iron ores is vital to the continued availability of iron and steel in our everyday lives (Eisele and Kawatra, 2003;Kawatra and Claremboux,

Bavarder sur Internet

Iron Ore in India , Types, Uses, Distribution, World Map

2024.9.27 Natural ore, also known as “direct shipping ore,” is ore that contains a high percentage of hematite or magnetite (more than 60% iron) and can be fed directly into blast

Bavarder sur Internet

Population balance model approach to ball mill

2014.1.1 The sample of coarse iron ore was characterized in laboratory tests carried out in a small batch ball mill. Selection and breakage function parameters were determined from the laboratory tests.

Bavarder sur Internet

Raw Mill, Cement Raw Mill, Raw Mill In Cement

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials

Bavarder sur Internet

Exploring Low-Grade Iron Ore Beneficiation

2024.8.2 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand

Bavarder sur Internet

Review on vertical roller mill in cement industry its

2021.1.1 Raw mix, high grade limestone, sand and iron ore are transported from their bins to raw mills for drying and further fine grinding. The raw mill is either a Ball mill with two

Bavarder sur Internet

Reduction of Iron Ore Pellets: A Microstructural Perspective?

2023.12.8 Twenty different iron ore pellets, consisting primarily of Hematite (Fe2O3) phase, were subjected to ‘simulated’ reduction studies. A wide range of reduction time periods,

Bavarder sur Internet

Why Is Iron Ore Valuable? Behind the Scenes of Production

2022.2.3 Statistics on iron production generally break out the usable iron ore and iron content into separate categories. The production of iron takes place in three steps: Extraction;

Bavarder sur Internet

Iron Ore Beneficiation Plant Equipment For Mining Process

2023.9.4 Iron ore pre-treatment equipment. The pre-treatment stage of iron ore mainly includes crushing, screening, grinding, and grading processes.. Crushing and screening: The

Bavarder sur Internet

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009.1.1 The iron ore beneficiation plants normally include a series stages of size reduction (in order to achieve the desired liberation degree), increasing iron ore grade

Bavarder sur Internet

Sintering: A Step Between Mining Iron Ore and Steelmaking

2019.6.11 The remaining 2% of domestic iron ore was produced for non-steel end uses. Seven open-pit iron ore mines (each with associated concentration and pelletizing plants), and

Bavarder sur Internet

(PDF) Beneficiation and flowsheet development of a low grade iron ore ...

2020.12.1 In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied. The Run of Mine (R.O.M) sample assayed 21.91 % Fe, which is

Bavarder sur Internet

Articles liés

- rumus nfs underground 2

- roi riche fraiser des pièces de rechange

- 11 l'impact de l'usine de concasseur à marteaux alimenté

- types de concasseurs de cimentation

- processus d extraction de l or en afrique du sud

- feldspath et de Gravier de traitement

- broyeur de pierres plus t t

- solutions marteau de concassage

- costo de maquinaria para la guar gum molino

- Laver le sable usine Indonésie Duba

- Procédé de la construction du minerai d cuivre

- jc2248 concasseur Indonésie mâchoires

- concasseurs de roche d'explication

- types concasseurs de roche

- balle fraiseuse en malaisie

- composition de poussiere de concassage

- concasseur Indonésie mâchoires pex 250 x

- liste des sociétés miniè;res en namibie

- Matrice Fournisseur De Broyage A Boulets

- séparateur magnétique machines sable de fer

- Rapport sur le projet de minerai de fer de l'usine d'enrichissement Stemcor

- marteau de qualité supérieure concasseur

- piezas de repuesto para molino vertical alliant

- normes de bandes transporteuses Tunisie

- alimentateur vibrant grizzly pour le calcaire

- concasseur à sable écologique

- grands moulins Indonésie billes

- et végétales de la carrière Indonésie Ica

- acieries de la plaque

- concasseur et lusine de lecran pour la vente japon